Leading Tech

About us

Company Profile

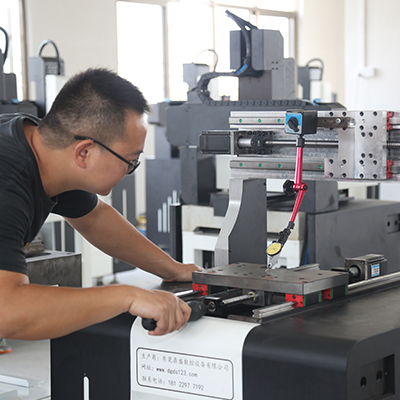

DingSheng CNC Equipment, a leading manufacturer of CNC engraving equipment in China, has been deeply engaged in the industry for years. Our mission is to offer high – precision and high – efficiency intelligent engraving equipment, along with customized solutions, to customers worldwide. Guided by the core philosophy of “Striving for perfection and pursuing excellence”, we rely on our advanced technology R & D team and strict quality control system. We are dedicated to the R & D, production, and sales of core equipment like CNC engraving machines, precision engraving machines, and CNC routers, facilitating precision processing and efficient production across various industries.

1.Who are we?

We are Dongguan Dingsheng CNC Equipment Co., Ltd. Specializing in the design, R & D, production and sales of fine – carving machines, we have established a good reputation in the field of precision CNC engraving equipment. Committed to providing customers with high – quality products and professional pre – sales and after – sales services, we focus on meeting the diverse processing needs of different industries, from ceramic, hot – stamping to glass, hardware and other fields.

Fast Facts

- Establishment: Dongguan – based, focusing on CNC engraving equipment R & D, production and sales for years.

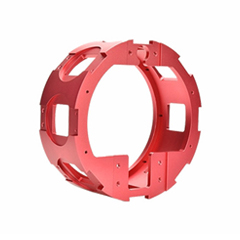

- Core Products: Multi – functional fine carving machines, supporting milling, drilling, cutting, etc.

- Industry Reach: Serve ceramics, hardware, electronics industries, cooperating with universities and enterprises.

- Tech & Patents: Own proprietary technologies and patents, ensuring product innovation.

Core Products

Precise Manufacturing, Diverse Adaptability

CNC Engraving Machine Series

High – Precision Machining: Our CNC engraving machines feature imported servo systems and marble – made precision machine bodies. With a positioning accuracy of ≤ ±0.01mm and a repeat positioning accuracy of ≤ ±0.008mm, they can ensure extremely delicate processing of complex surfaces.

High – Efficiency Production Capacity: The spindle speed of these machines can reach up to 24,000 revolutions per minute. Equipped with an automatic vector frequency converter, they support integrated processing of multiple processes such as high – speed engraving, milling, and drilling, increasing production efficiency by over 30%.

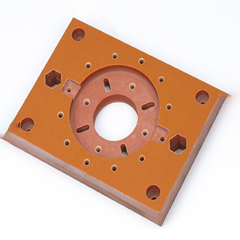

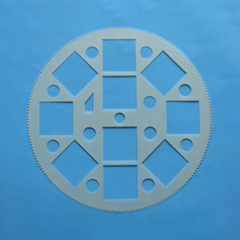

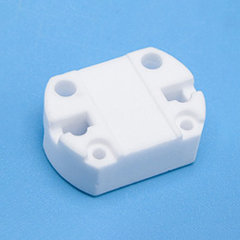

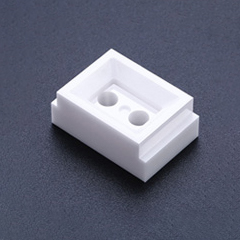

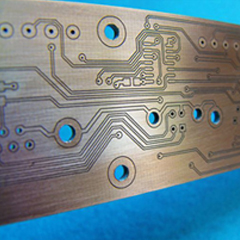

Material Compatibility: They are compatible with numerous materials, including aluminum alloy, brass, acrylic, ceramic, and carbon fiber. This makes them widely applicable in fields such as hardware processing, electronic manufacturing, and handicraft engraving.

Precision Engraving Machine Series

The First Choice for Precision Machining: Specifically designed for high – precision requirements, our precision engraving machines support 0.001mm – level micro – engraving. They are ideal for fine processing of optical lenses, jewelry accessories, 3C product casings, and more.

Intelligent Five – Axis Linkage: The five – axis models can perform 360° three – dimensional engraving. They can easily handle complex surfaces and multi – dimensional processing, meeting the demands of high – end fields like molds and medical devices.

CNC Router Series

The Cost – Effective Option: Our CNC routers combine rigidity and stability. They can process large – size workpieces (with a maximum stroke option of 1325mm), come with a standard intelligent control system, are easy to operate, and offer excellent cost – performance.

Customizable Configuration: We can customize the spindle power, tool system, and automation module according to customers’ specific needs, making these machines suitable for production in various scenarios such as woodworking, stone processing, and metalworking.

2.What do we do?

We are engaged in the whole process of fine – carving machine business, including design, R & D, production and sales. Our fine – carving machines are capable of processing a wide range of materials and products. They can handle ceramic industry parts, hot – stamping samples, glass samples, hardware components and non – metal parts. We also provide core services such as servo motors (including hybrid servo motors and original Panasonic servos) and high – speed precision electric spindles. Additionally, we offer CNC operation systems with multiple practical features to ensure efficient and accurate processing, covering functions like milling, drilling, tapping, cutting, high – gloss (chamfering), and polishing.

3.Why choose us?

We offer precision – engineered carving machines with stable performance, covering diverse materials like ceramics and metals. Backed by strict quality checks, professional craftsmanship, and responsive service, we ensure efficiency and reliability for your projects.

Fast facts

Philosophies and Values

Values: Unite and strive, be loyal to the Sealoff cause; adopt scientific management to improve corporate efficiency; provide sincere services to create value and success for customers.

Customer Philosophy: Centered on customer satisfaction, actively respond to customer needs.

Management Philosophy: Care for people, respect people, cultivate people, and achieve people.

Service Philosophy: Sincere, patient, meticulous, warm, loving, and attentive.

Execution Philosophy: Attitude determines everything, and details determine success or failure.

Quality Philosophy: All – employee participation, continuous improvement, and prevention of problems before they arise.

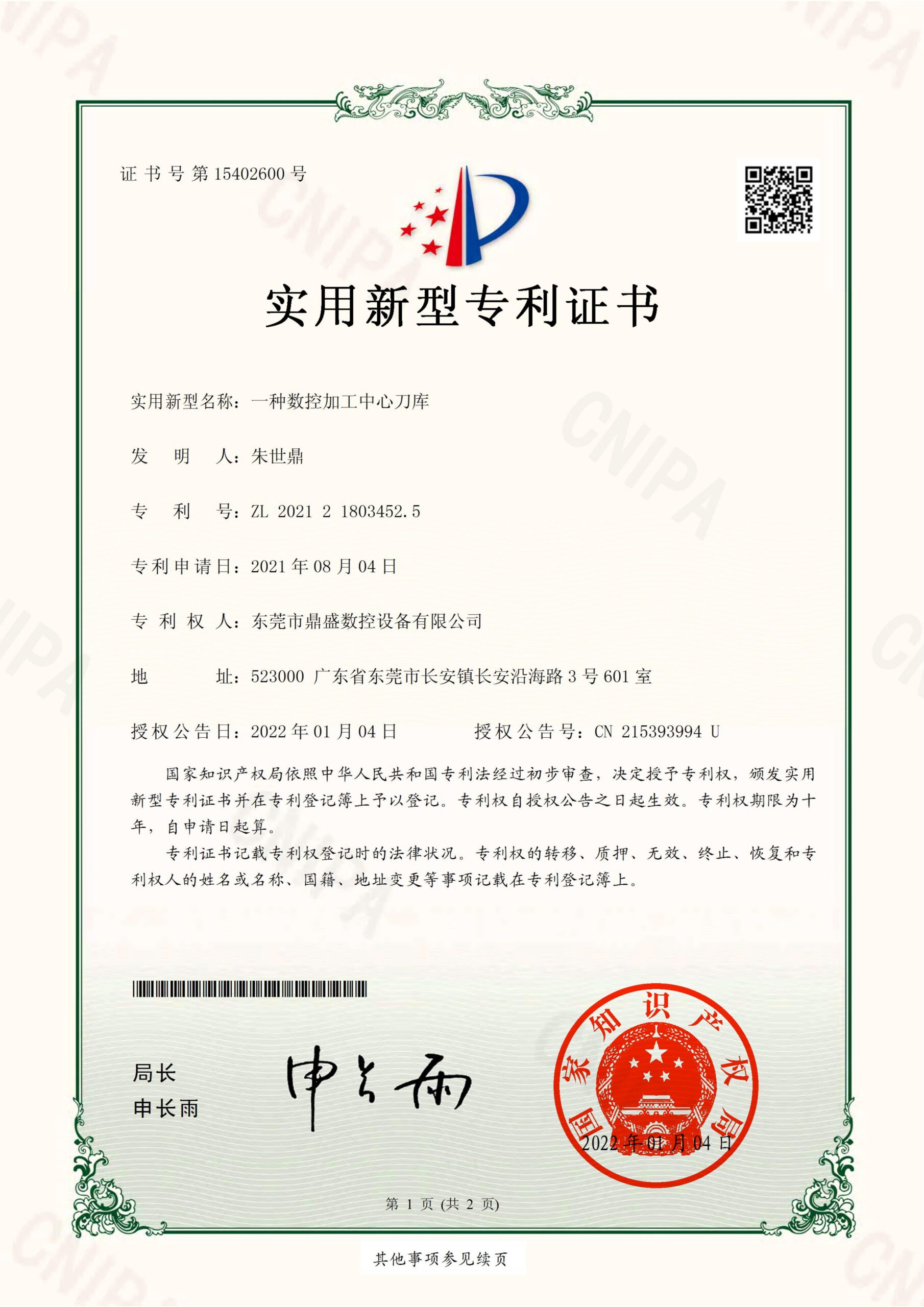

Certification Qualification

We own a utility model patent for a CNC tool magazine (Patent No. ZL 2021 2 1803452.5). With a valid business license (Credit Code: 91441900MA52M96C9Y), we ensure reliable CNC equipment R & D and sales.

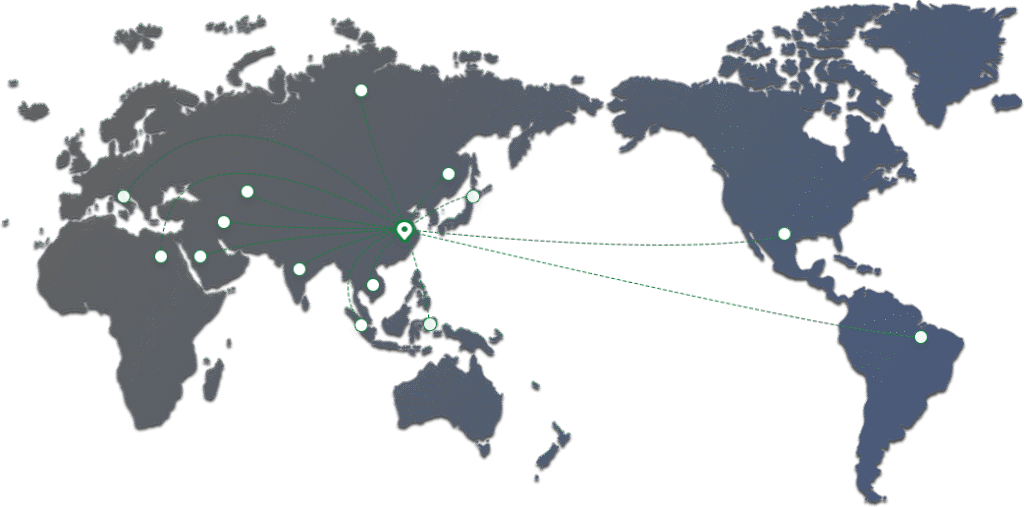

Sales network

The products are mainly exported to the United States, Japan, Australia, Europe, the Middle East and other countries and regions

It is popular in countries such as Europe, America and Southeast Asia all over the world